CHENGDU, China – This Wednesday, a three-member delegation from Thailand arrived at ZETATECH for an extensive on-site inspection and high-level business negotiations. The visit aimed to evaluate ZETATECH’s manufacturing capabilities, core business ecosystem, and market competitiveness in the energy storage sector. Senior leadership and technical teams provided a comprehensive guided tour, fostering a strong consensus for future collaboration.

Advanced Manufacturing and Quality Assurance

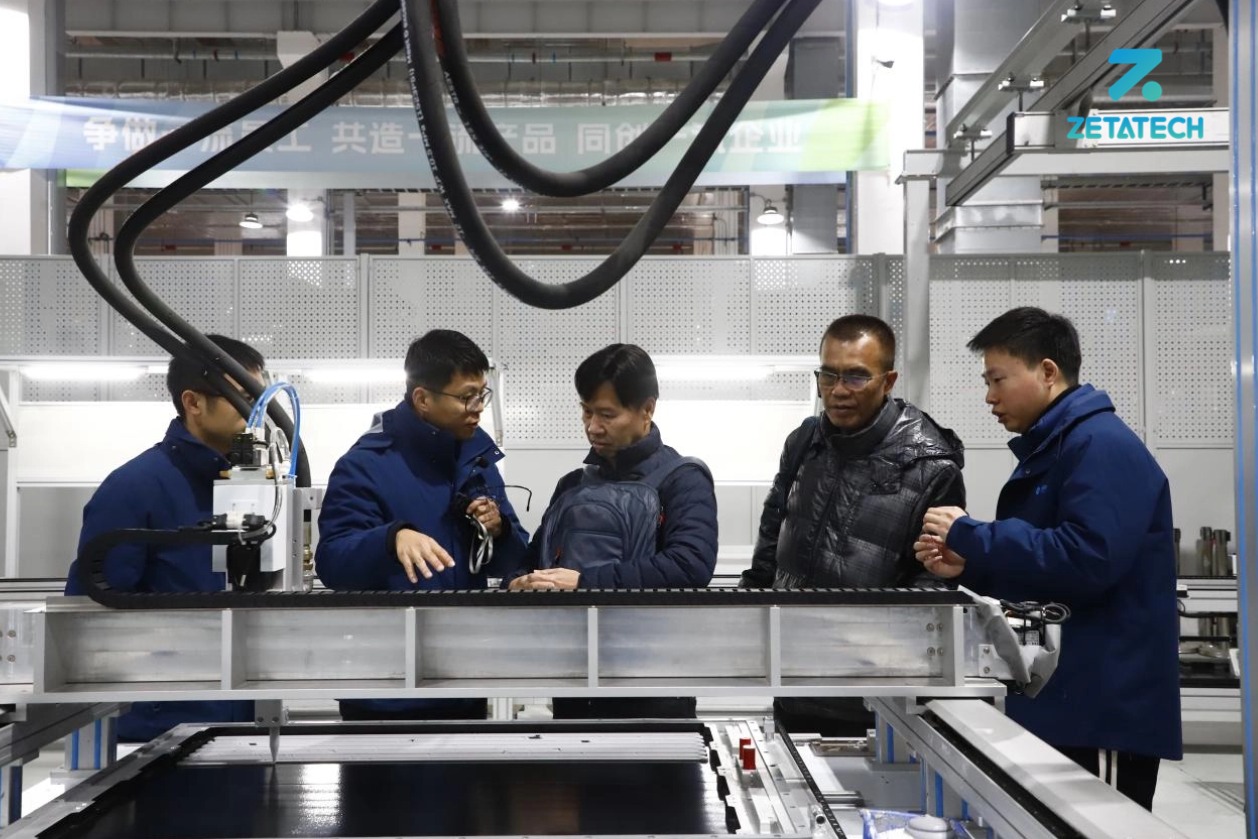

The delegation’s first stop was the Antai Production Base, the heart of ZETATECH’s energy storage operations. Spanning over 50 acres, the facility currently operates two automated production lines. Running on a steady schedule, the plant boasts an annual capacity of 2.3GWh to meet surging global demand.

The clients conducted a deep dive into the end-to-end manufacturing process of battery modules, packs, and cabinets. They paid close attention to critical quality control stages, including OCV sorting, polarity testing, post-weld inspection, and EOL (End-of-Life) testing. The tour continued to the testing labs, where the delegation observed the rigorous charge-discharge cycles and functional verification protocols that every unit undergoes before leaving the factory.

A Diverse Product Portfolio

In the exhibition area, the delegation explored three of ZETATECH’s flagship solutions:

Zetacube 261kWh Commercial & Industriel (C&I) ESS: A proven performer already deployed across Africa, Europe, and South America.

All-in-One High/Low Voltage Systems: A favorite in the European residential market due to their "plug-and-play" installation and modular scalability.

Rack-Mounted Batteries: Highly competitive in the African market for their exceptional cost-performance ratio and flexible expansion options.

Corporate Vision and Strategic Alignment

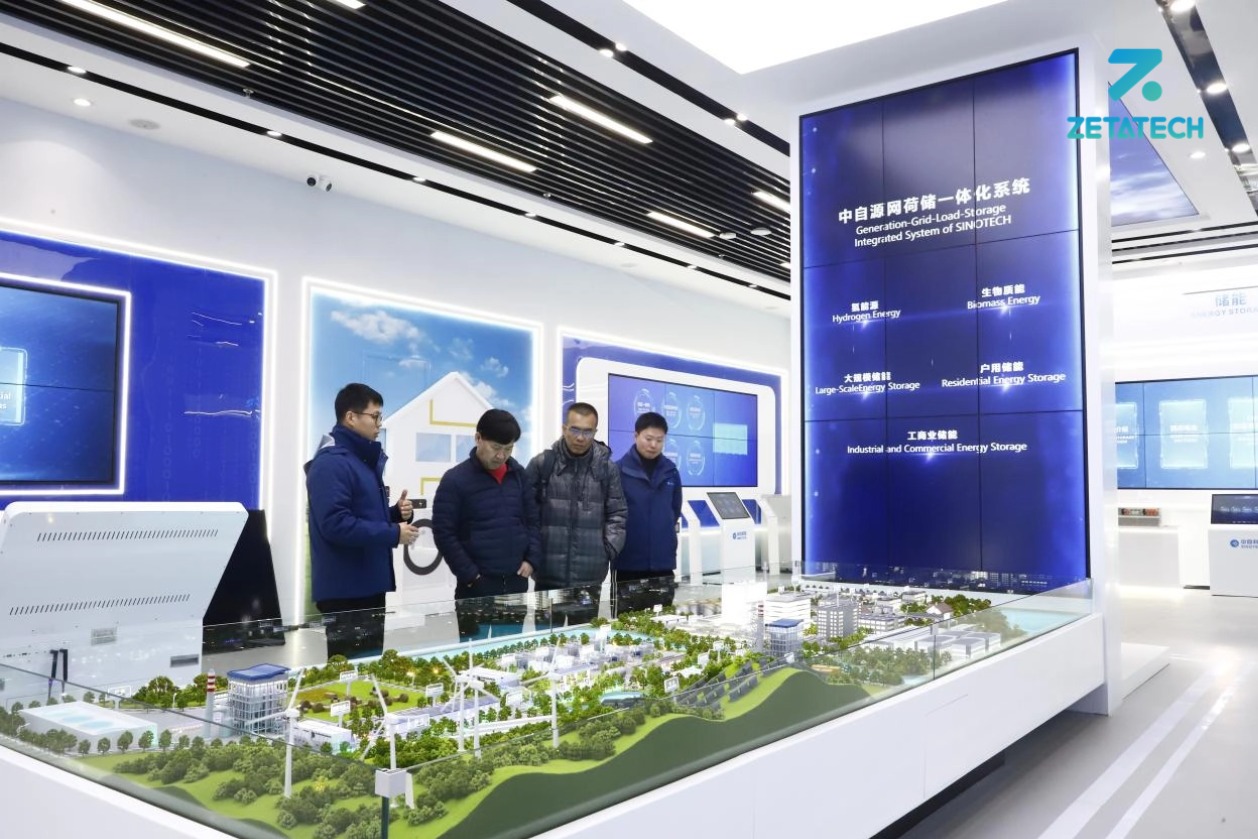

Following the factory tour, the guests visited the corporate headquarters to tour the newly built exhibition hall. The exhibition details the company’s 20-year legacy, highlighting corporate growth, social responsibility, and its three core business pillars: Catalysts, Energy Storage, and Composite Materials. Through interactive sandboxes and multimedia displays, the clients gained a holistic view of SINOTECH’s diversified industrial layout.

Sealing the Partnership

The visit culminated in a strategic meeting between the Thai delegation and ZETATECH’s senior executives. The discussions focused on the specific demands of the Thai energy market, product customization, and localized marketing strategies.

The meeting concluded with the formal signing of a cooperation agreement. Both parties committed to jointly developing the Thai residential and industrial energy storage markets, leveraging their respective strengths for mutual success. This partnership marks a significant milestone in ZETATECH’s expansion into the Southeast Asian market and underscores the deep trust shared by both organizations.